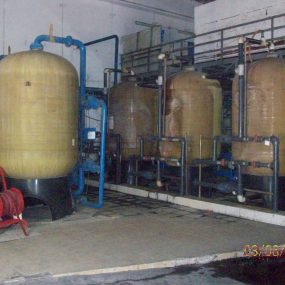

filtrationSystems

It uses granular media to retain sediment in the water.

Depending on the type of mineral used, the filter has several applications, including granular media filtration:

to remove colloidal turbidity after chemical treatment,

As a pre-filtration to protect processes

Cooling water filtration to prevent contamination of the heat exchanger

For drilling water filtration, iron and manganese removal

To protect chlorine removal, ion exchange resins or membranes in water

It is used in feed water for drip irrigation systems.

Media filter is manufactured as glass reinforced polyester (CTP) or steel.

Uses steel for dimensions of approximately 1,500 mm in diameter or larger.

Depth 1.5 m - filter bed is usually 1.

The filter usually has 30% space for filter bed expansion during backwashing. Sand, anthracite, granite, manganese dioxide, granular activated carbon, dolomite and other materials are used for special applications.

Water enters the tank from above and the media flows down through the bed, and is discharged at the bottom with a collector system.

The contaminant is removed through the mineral selected.

As water passes through the filter, a loss of load occurs because the contaminating minerals are trapped between them.

It is then taken out of service and backwashed with clean water.

Since the anthracite density is lower than that of the sand, it remains a separate layer during backwashing.

Multimedia filtration is sometimes used in two stages (usually anthracite and sand).

Chemicals such as polyelectrolyte can be added at different stages to increase filtration efficiency. Granular activated carbon is widely used to remove chlorine from mains water.

Ion exchange can be used before reverse osmosis because it does not cause damage to resin or membranes.

With activated carbon filtration, dechlorination removes chlorine and bad taste.

Activated carbon filters; chlorinated hydrocarbons are used to remove organic chemicals such as pesticides and species, such as flavor, smell and color.

Manganese dioxide is used as a catalyst filter bed to remove water, iron and manganese in a series of boreholes in industrial applications.

Dolomite is sometimes used as a separate layer on sand, filters, to neutralize low pH water alone. The media melts slowly and needs to be replaced at regular intervals.

Since the filtration is a collective process, tanks with two or more filters are made so that the filtration can continue to the service while the filters are in a backwash.

For performance, the water velocity should not exceed 20 m / h. In particulate waters, the media should be suspended solids to the filters and preferably at least 10 mg / l.

Grain media will usually achieve this better performance by using grain size 0.5-1.0 mm grit, bed depth 1 m filters set to increase the efficiency of all particles larger than 2 μm to 98%.

Typical filtered water, suspended solids will be less than 2 mg / l and turbidity will normally be less than 1 NTU.

Backwashing in the 24-hour service takes about ½ hour, the loss of load through a filter depends on the current (filtration rate), media grain size and bed depth.